visual

location

Overview

Overview

SAE-A’s supply chain is fully vertically integrated. Our capabilities include best-in-industry research, leading design work, production of garments and superior retail experience. This allows us to provide our clients with a fully complete experience from concept to product. Tracing the production of a garment from concept to completion illustrates SAE-A's work. The production of a cotton garment is best summarized in 10 processes:

Product Development & Design

From our founding, we have worked to provide customers with the highest quality products and production services. In 2001, we added design and research and development capabilities helping us best understand and integrate the customer’s vision from concept to creation. Several of the components of these efforts include:

Fabric Research & Design (R&D)

-

Making Presentation Tool

Making Presentation Tool

-

Conducted Fabric Show and Seminars

Conducted Fabric Show and Seminars

-

Fabric Library

Fabric Library

-

In R&D, SAE-A :

- Conducts research, analyze market trends based on customer's needs.

- Established fabric library capacity in New York, Los Angeles and Seoul offices for client engagement.

- Update fabric library and manufacturing options regularly.

Design

-

As part of the design process, SAE-A :

- Conducts seasonal, graphic, wash and fabric trend research in US, Europe and Japan.

- Develops garments based on global trends and customers’ concepts.

- Customizes services based on customers’ needs.

Technical Design

-

In technical design, SAE-A :

- Review sample pattern & fit for best quality garments.

- Employ dedicated technical design specialists to meet the specification of customers.

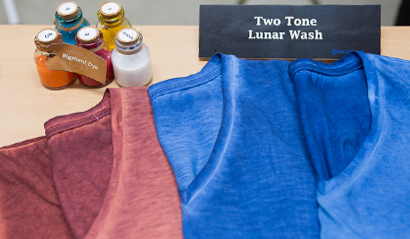

Wash Innovation

-

In wash innovation, SAE-A :

- Provide customers with full up-to-date washing trends and techniques.

- Ensure garment washes meet clients’ expectations and needs.

International Trend Research

-

SAE-A conducts international trend research, including :

- Set up a fabric library & showrooms in New York and Bentonville.

- Customize trend and market research for our customers.

- Deliver results to product development & design department at SAE-A's head office.

Manufacturing

SAE-A's apparel manufacturing process spans the entire supply chain from working with customers on design and fabric selection to the delivery of finished garments.

There are three main components of the manufacturing process:

- Pre-Production : including sampling materials, sourcing of raw materials, pre-production meetings, and finalizing approvals.

- Production : including receiving all materials including fabric, garment production, and cut ans sew activities.

- Post production : including finishing processes, quality checks, packing, and shipment inspection.

To increase efficiency and ensuring the highest quality, SAE-A has established complete vertical integration by bringing the entire process under one umbrella. To do this, we have applied a Lean Management system.

Realizing Vertical Integration

Seeking to reduce costs, improve quality and streamline our supply chain, SAE-A has worked to realize full vertical integration. One example of vertical intergration is the Spinning Mill in Costa Rica that supplements fabric production and reduces overall production lead time.

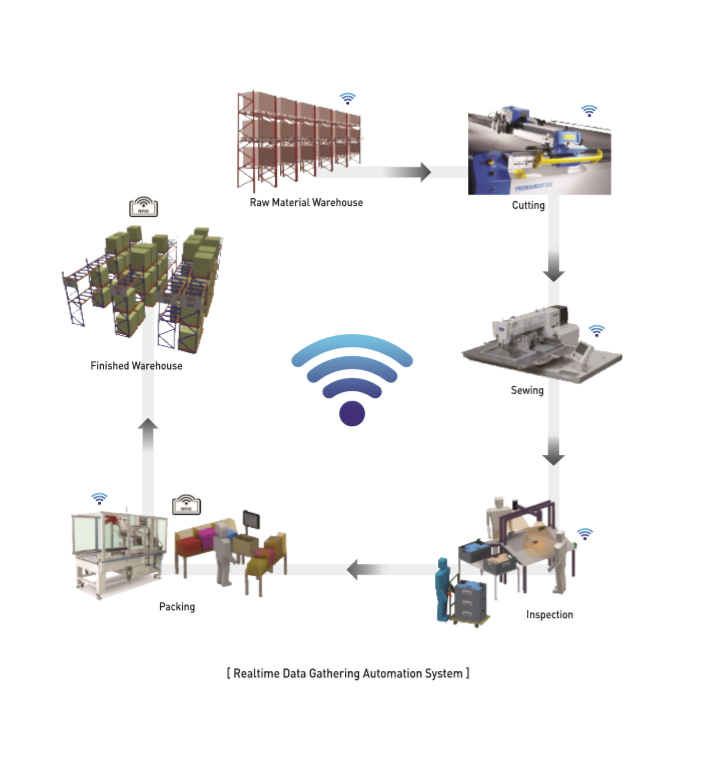

Smart manufacturing

- MES (Manufacturing Execution System)

: Will support smarter decision making by applying the MES (Manufacturing Execution System) which optimizes the management of both manufacturing and operations while making all data from the manufacturing floor immediately available and easily accessible according to the following schedule:

Step 1

l Sewing automation means real-time production monitoring through sensors installed at each sewing machine

l QC automation takes the digital data from the test results and records in real-time.

l Packaging automation will automate many of the existing manual functions and also provide for real-time production flow and output monitoring

Step 2

l Cutting automation will maximize efficiency through network connected machinery.

l Warehouse automation allows for real-time inventory management and optimizes operations by introducing a computerized warehouse management system.

- WMS (Warehouse Management System)

: Provides real-time updates of the flow of materials in and out of the warehouse while optimizing the logistics of shipping, receiving and inventory management by maximizing the use of computerized equipment and minimizing space within the distribution center under one centralized warehouse management system.

What is "Lean Management"?

Lean Management is the process through which SAE-A focuses on value and safety to achieve our goal of providing the best quality product. The company has established its own rules of Lean Management that promote best practices, process, eliminate waste, and ultimately standardize best practices. As with the majority of SAE-A's initiatives, training is critical to the implementation of these practices and we provide courses and training to all employees across the company.

SAE-A also encourage all of our facilities to provide suggestions for improving work-flow, efficiency, work experience, and quality of the end product. Suggestions from our facilities have become best practices across the company.

Quality Assurance

SAE-A’s quality assurance protocols ensure SAE-A facilities maintain the highest production standards, and in turn, highest levels of customer satisfaction.

The Five Key Elements of Quality Assurance at SAE-A

- 5 key tasks

- Automation System

- Tooling System

- Standardized Testing

- Supplier Management

- Employee Education

- Technology

- Ensure employees use the latest technology to maintain the highest levels of quality.

- Production Systems

- Train employees to help improve efficiency and consistency.

- Quality Inspections

- Leverage technology and employee knowledge to ensure every product meets high standards

- Partnership with Suppliers

- Work with suppliers to comply with certification systems.

- Internal Improvements

- Continually review, refine and improve our processes.

Performance Material

AdvancedHeat Technology

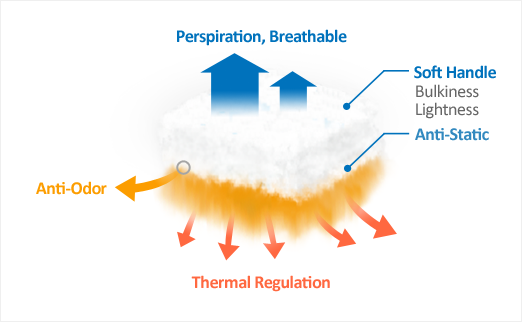

Aeroheat

- Absorbs the thermal energy from the body and re-emits

- Light and very soft handle

- Wicking and breathable

Heat Technology

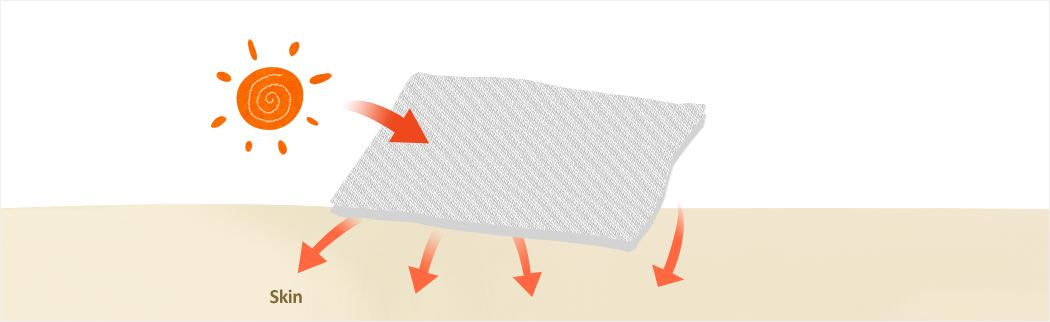

Carbono

- Special fabric coated with carbon nano tubes

- Absorbs the solar energy and re-emits it into far infrared rays

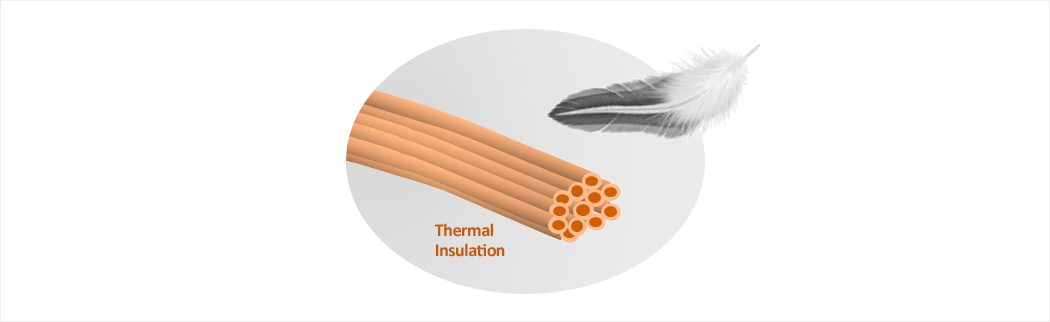

Breeze warm

- Layers of air created by special yarn keep the body warm

- Lighter than conventional materials

AdvancedCooling Technology

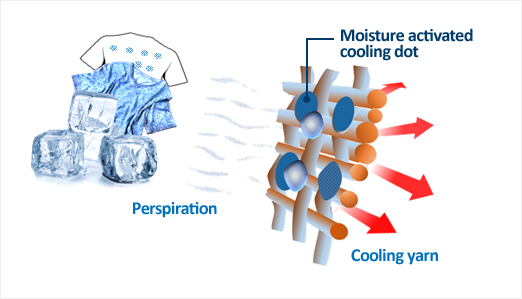

Springer

- Particles in the yarn prevent UV rays from penetration

- Releases heat to keep the body cool & dry

- Sweat activated cooling technology gives increased comfort

Cooling Technology

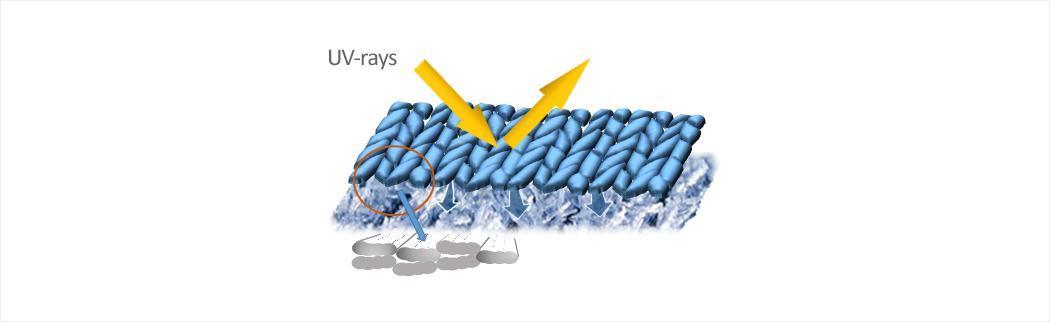

Ice-ever

- Flat yarn increases the surface area of contact with bare skin, helps release body heat from the clothes

- Special minerals in the yarn keep body cool and prevent transmission of UV-rays

- Opaque material for light colors

- Wicking and quick dry

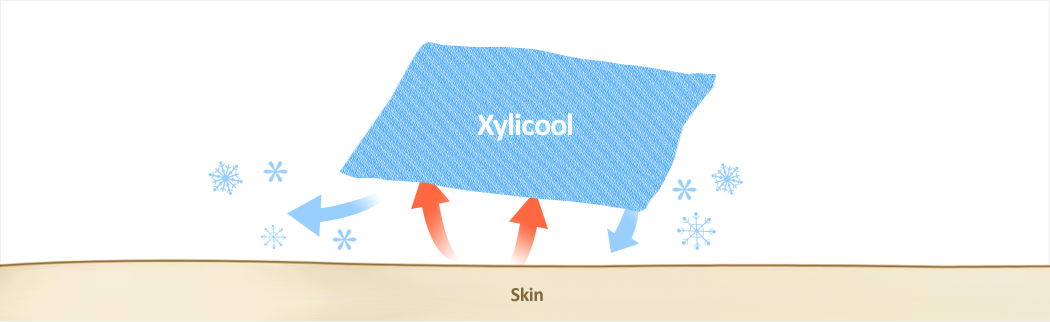

Xylicool

- Cool to the touch

- Extremely durable after repeated washes

Stretch

AdvancedStretch Material

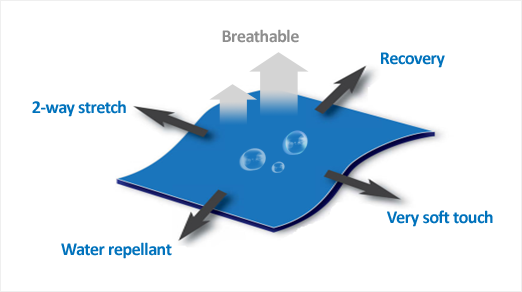

Omni-Span

- Soft to the touch

- Light weight

- Superior stretch and recovery

- Better wet fastness and chlorine resistance